Every effort is made to ensure that technical specifications are accurate. However, technical specifications included herein should be used as a guideline only. All specifications are subject to change without notice.

Cobalt Alloy MP35N® (2.4782) Medical Alloy

Alloy MP35N® is a Vacuum Induction Melt / Vacuum Arc Remelt (VIM/VAR) cobalt alloy which obtains very high strength, corrosion resistance and fatigue resistance due to its two-stage cold working and aging treatment process. Machining is relatively difficult and not advised in the annealed condition so material is supplied in the solution treated and cold worked condition to allow for the final ageing stage. After aging, hardness levels can reach over 55 HRC and strengths levels as high as 260-300ksi.

Applications

Orthopedic implants

Joint replacement

Medical, surgical, dental instruments

Watch components

Aerospace industry

Micro-engineering

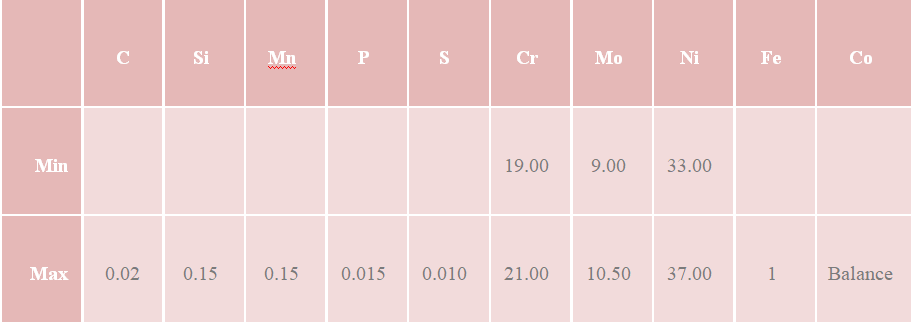

Typical Chemical Composition

Typical Mechanical Properties

Specifications

2.4782

ASTM F562

ISO 5832-6

AMS 5758

AMS 5844

AMS 5845

UNS R30035

Availability

Alloy MP35N® is available in

Precision ground Round bars : 6mm Dia to 60mm Dia x 3000mm long

Sheets / Plates : 1mm to 25mm thk x 500mm x 1500mm long

Wires : 0.20mm Dia to 4.5mm Dia X Coil / Straight Rods

Contact sales for more information

Disclaimer

1)50 years of combined experience

2)Full-service centre with global logistics expertise

3)Expert technical knowledge of metal specifications

1)Complete service from start to finish

2)Express global shipping

3)Same-day shipping on stock items

4)No minimum order quantity

1)Accredited to ISO 9001:2015 &

ISO 13485:2016

2)Experienced quality management team

3)Expert packing to ensure all orders arrive in perfect condition