Every effort is made to ensure that technical specifications are accurate. However, technical specifications included herein should be used as a guideline only. All specifications are subject to change without notice.

Stainless Steel 440C (1.4215) Medical Alloy

440C (1.4215) martensitic stainless steel is heat treatable to attain the highest levels of strength, hardness and wear resistance of all of the stainless steels. It has a higher carbon content than 440A and 440B giving it these characteristics, but at the expense of slightly reduced corrosion resistance. Typically used in applications such as bearings and rollers, its high hardness make it ideal for all types of surgical cutting instruments.

Applications

Medical instruments

Surgical instruments

Dental instruments

Cutting instruments

Typical Chemical Composition

Heat Treatment

Treatment : 1925 °F ± 25 (1052 °C ± 14), held at heat for 30 minutes ± 3, and quenched in oil.

Optional : Sub-zero cooling to -100 °F ± 20 (-73 °C ± 11), holding at that temperature for 2 hours ± 0.25, and warming in air to room temperature

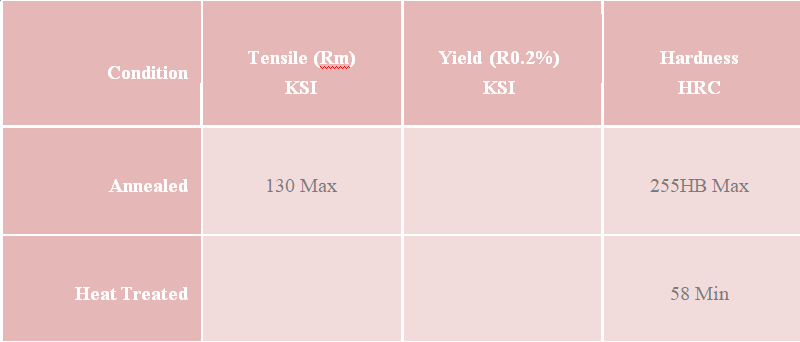

Typical Mechanical Properties

Specifications

1.4125

EN X105CrMo17

AFNOR X105CrMo17

ASTM F899

ASTM A959

NF S94-090

UNS S44004

AMS 5630

AMS 5618 Vac Melt

Availability

Stainless Steel 440C (1.4215) Medical Alloy is available

Precision ground Round bars : 6mm Dia to 60mm Dia x 3000mm long

Sheets / Plates : 1mm to 25mm thk x 500mm x 1500mm long

Wires : 0.20mm Dia to 4.5mm Dia X Coil / Straight Rods

Contact sales for more information

Disclaimer

1)50 years of combined experience

2)Full-service centre with global logistics expertise

3)Expert technical knowledge of metal specifications

1)Complete service from start to finish

2)Express global shipping

3)Same-day shipping on stock items

4)No minimum order quantity

1)Accredited to ISO 9001:2015 &

ISO 13485:2016

2)Experienced quality management team

3)Expert packing to ensure all orders arrive in perfect condition